your budget and stunts the growth of your business. To avoid this, you might want to be prepared. We have already covered the subject of

cracking and asphalt depressions. In this article, we would like to help you learn more about the factors, which can damage your pavement. We’ll also tell you about the types of preventive pavement maintenance that will save your time and budget. Before we start looking into the hows and whys of pavement distresses, it is important to know the difference between two main types of pavement:

Flexible pavement- Consists of a surface course, base course, sub-base course and subgrade.

- The flexible pavement is designed to handle the load intensity by distributing it between layers, instead of putting only the surface level under pressure.

Rigid pavement- Features structured cement concrete slabs on the top of the base and subgrade course.

- The rigid pavement relies on the strength of the concrete, so the subgrade course doesn’t really take part in handling the load.

Why is it important? Each pavement type is prone to a certain kind of damage and requires specific repairs. For example, the technique used to fix a concrete slab won’t work for a cracked flexible pavement. OK, now you are ready. Let’s get started.

CAUSES OF PAVEMENT DISTRESS

Load-related distress. This category includes damages caused by the traffic load. Polished aggregate, rutting, and stripping are the bright examples of such deformities. Non-load related distress. Another main cause of pavement deformities, aside from the traffic load, is the age hardening of asphalt. When the layers are worn down by climate or because of the poor quality of materials (sometimes, the combination of these factors is at fault), it breaks the integrity of the pavement surface, resulting in such distresses as popouts, swelling, cracking, etc.

WHY A FULL-SCALE PAVEMENT REPAIR WILL COST YOU A FORTUNE?

WHY A FULL-SCALE PAVEMENT REPAIR WILL COST YOU A FORTUNE?

Renovating or repairing your pavement is not the cheapest procedure. The more complicated the damage is, the more resources the repair team needs to fix it. Aside from full reconstruction of the lot, the most common ways to fix the pavement distress are partial depth patch and full depth patch.

- Partial depth patch implies removal of the surface layer and replacing it with a patch made of new, more durable materials.

- Within a full-depth patch, all layers are removed and replaced.

- These types of repairs include cleaning, drying, cutting, as well as the cost of materials in their total price.

This is a weighty argument why you shouldn’t neglect your pavement. Using preventive measures is beneficial to you in the first place. You make an investment in the life of your pavement as well as the safety of the clients, who come to your property.

How Often Does Asphalt Pavement Need Repairs?

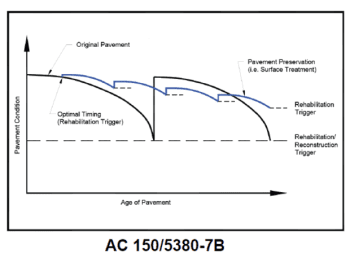

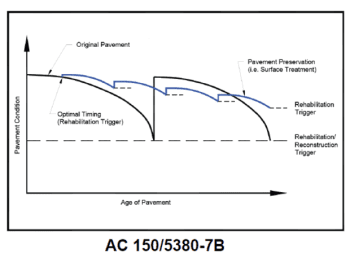

When it comes to determining when to do repairs, this chart illustrates the following.The condition of the pavement directly depends on its age. The newly-laid pavement has the perfect binding between the layer, which means its integrity is top-notch, so a routine maintenance is sufficient.

- After 3-5 years the situation changes and the need for asphalt repairs increases.The surface and layers face the first signs of deterioration, intensified by the weather, traffic load or other environment factors. While their severity depends on the quality of materials and basic maintenance (cleaning, washing, etc.), the first preventive maintenance measures are in order. Timely application of preventive pavement repairs within 3 to 5 years will extend the life of the surface for 3 more years.

- As the pavement ages, it requires more comprehensive maintenance, and, ultimately, a reconstruction. However, when the maintenance and repair schedule is followed, the final reconstruction of your lot will require fewer resources and take less time. Therefore, you will be able to save up on the full-scale renovation of your property.

- According to this, a profitable and money-saving pavement maintenance consists of timely applied preventive measures, which in turn lead to a faster and easier full renovation.

PAVEMENT PRESERVATION TECHNIQUES

Crack sealing and filling. The best preventive solution to weathering or swelling is filling the cracks with a high-quality crack filler that will hold the surface together and protect it from the water penetration, frost-heaving and other harmful climate effects. However, crack filling does not work against rutting, stripping, alligator cracking or any other extensive structural damage. Slurry seals. This technique implies applying an extremely thin layer of top quality aggregate, emulsified asphalt and additives to the pavement surface. This way, the pavement is sealed and granted a shield against water damage, heat damage and air damage, which in turn prevents swelling, joint spall and corner spall. Chip seals. Within this procedure, the team applies a special protective layer to the existing surface. Such technique is used to prevent raveling or cracking of the aged layers. Chip seals are not recommended against potholes or rutting and vulnerable to bleeding. Micro-surfacing. Similar to a slurry seal, micro-surfacing is covering the surface with a mixture of chemicals, additives (water, mineral fillers), high-quality aggregate and emulsified polymer-modified asphalt. This new layer improves skid resistance, prevents aging, levels the surface, hides and fills the cracks and also can fix any issues that come along with a moderate rutting. Thin overlays. If you have problems with loss of skid resistance or weathering, applying a very thin layer of pavement on the leveled surface will save your day and make your asphalted property more usable. A thin overlay can prevent aging or rutting. Cleaning. The simplest of the procedures that you can perform personally. Clean your pavement and pressure-wash it regularly to remove chemicals and contaminants from the surface.

WHAT HAPPENS WHEN YOU DON’T FOLLOW THE SCHEDULE?

If you ignore the condition of your pavement, never perform a condition check after a frosty winter or a rainy season, these are deformities you’ll end up dealing with. These damages usually involve all pavement layers and require in-depth repairs, which will take a lot of funds from your budget.

CRACKING

Durability cracking. Also known as D-cracking and caused by the large aggregate freeze-thaw expansion, these deformities look like numerous crescent-shaped cracks. They are usually located near a crack, corner or joint. The issue is typical for rigid pavements and solved with the help of the partial depth patch or the full-depth patch. Shrinkage cracking. This is the term for very thin cracks that are not located anywhere near the joints. This type of cracks doesn’t go deep into the pavement structure. Sometimes shrinkage cracking can be very extensive – in this case it is considered a serious distress and fixed with the help of crack sealing. Shrinkage cracking is common in rigid pavements made of PCC (Portland Cement Concrete) and occurs in case of bad setting and curing. Shattered slab. Breaking of a slab due to large load, bad weather conditions or poor quality of materials. Such kind of damage renders the entire lot unusable, so a full replacement is the only option.

DISINTEGRATION

Weathering. When the weather (cold, excessive moisture, frost shattering) affects the structure of the pavement surface, it is called weathering. The common result of weathering is cracking, chipping of the pavement surface, roughening or increased surface porousness. The solution to this issue is usually defined after a damage analysis. Stripping. Stripping is a surface crack that goes from the bottom of the surface layer and upwards. It happens when the bond between asphalt binder and aggregates is lost. While the factors that cause the bond loss and stripping still require more research, the experts ascribe this kind of disintegration to water damage, because the hydrophobic aggregates usually do not face stripping issues. Blowup. This is the name for a slab that gets cracked or shattered at a joint because of a localized upward movement. This type of distress is caused by hot weather, freeze-thaw damage or D-cracking, creating a serious and hazardous damage. Blowups are repaired with the help of the full-depth patch. Popout. The pockmark-like markings or divots usually appear in PCC due to the poor aggregate durability. They can be repaired with the help of the partial depth patch. Corner spall. The crack intersecting the corner at the joint of the PCC slab is defined as a corner spall. This type of distress is an evidence of the high stress and load applied to the corner of the slab. The pavement exhibiting corner spalls is more vulnerable to moisture infiltration, provides less support and leads to surface disintegration. Joint spall. When the edges of a joint or crack get broken, chipped or cracked, this is called joint spall. Poor quality of materials, heavy traffic load, disintegration of PCC caused by freeze-thaw action are the most common factors that lead to this type of damage. Patching. It is a patch failure. When a patch of new material is applied sloppily to the existing pavement, it makes the surface rougher and, therefore, less usable. Many professionals consider even well-performing patches a defect, because only smooth and intact pavement is an option.

DISTORTION

Pumping. This is the term for the pavement roughness, vehicle hydroplaning (due to water filling the raveled areas) and loose debris. This distress significantly reduces the usability of the pavement and occurs when the bond between the asphalt binder and particles disappears (asphalt binder aging, poor dust coating bonding, surface aggregate segregation, poor construction). The repairs usually include removing the damaged area and either applying a patch (if the area is small) or a removal and overlay of the damaged layer if the area is large. Rutting. This is the type of pavement distress that looks like wheel path depressions. Much like bird baths, ruts get filled with water each time it rains. Rutting occurs in the case of the incompatibility between the pavement surface and subgrade. There are two types of subgrade/surface issues. First, if the subgrade already has ruts because of the load and the pavement follows right in. Second, if it is the surface that exhibits ruts and subgrade caves in under the pressure. In any case, pavement rutting is hazardous for vehicle as the ruts have a tendency to pull vehicles towards the rut path, which can result in an accident. Leveling and overlay is the solution against rutting. Shoving. If you see the deformities that look like waves on the pavement surface, it means that the pavement suffers from the distress known as shoving. As these formations stretch perpendicular to the direction of pedestrians and traffic, they can cause a great inconvenience. The repairs of small areas that exhibit shoving usually consist of removal and patching. However, if the distressed area is large, only an overlay can fix the issue. Swelling. Localized upward bulges on the asphalt surface are the result of swelling. In its turn, swelling is the result of soil expansion because of the moisture or the growth of ice lenses beneath the surface layer. Because this damage goes beyond the surface level, a full-depth patch is the best solution.

LOSS OF SKID RESISTANCE

Polished aggregate. Small amount or complete lack of rough aggregate particles is called polished aggregate. This usually happens because the aggregate literally gets polished out by traffic. As the result, the skid resistance is decreased, so the area becomes dangerous for vehicles. Bleeding. This is the name for a smooth, shiny black film on the asphalt surface. This is caused by the pavement surface moving upwards because of hot weather, poor mix quality or excessive amount of asphalt in asphalt concrete. This distress removes skid resistance, leaving vehicles vulnerable to hydroplaning. Contaminants. Any chemicals spilled across the pavement surface have a corroding effect, so they eat through the layers and gradually destroy the integrity of the pavement. Spilled antifreeze or similar chemicals are the most common cause of skid resistance. Oil or fuel slippage. Spilled oil or petroleum contain solvents that erode and ruin the pavement surface. Therefore, any oil spots and spills must be cleaned immediately and not left unattended.

IS THAT’S ALL?

Far from it. Not only neglected pavement looks ugly and becomes a hazard, it also usually comprises an entire mixture of distresses. Only professionals are certified to define the causes and suggest necessary repairs. Our

Baltimore asphalt contractors operate in Maryland, Washington, D.C. and Delaware, so we can take a look, make a full report on your lot’s condition and suggest you a set of procedure that will restore the usability and great look of your property. We’ll keep an eye on your lot and timely perform the necessary procedures, ensuring the longevity and durability of your pavement.

WHY A FULL-SCALE PAVEMENT REPAIR WILL COST YOU A FORTUNE?

WHY A FULL-SCALE PAVEMENT REPAIR WILL COST YOU A FORTUNE? Durability cracking. Also known as D-cracking and caused by the large aggregate freeze-thaw expansion, these deformities look like numerous crescent-shaped cracks. They are usually located near a crack, corner or joint. The issue is typical for rigid pavements and solved with the help of the partial depth patch or the full-depth patch. Shrinkage cracking. This is the term for very thin cracks that are not located anywhere near the joints. This type of cracks doesn’t go deep into the pavement structure. Sometimes shrinkage cracking can be very extensive – in this case it is considered a serious distress and fixed with the help of crack sealing. Shrinkage cracking is common in rigid pavements made of PCC (Portland Cement Concrete) and occurs in case of bad setting and curing. Shattered slab. Breaking of a slab due to large load, bad weather conditions or poor quality of materials. Such kind of damage renders the entire lot unusable, so a full replacement is the only option.

Durability cracking. Also known as D-cracking and caused by the large aggregate freeze-thaw expansion, these deformities look like numerous crescent-shaped cracks. They are usually located near a crack, corner or joint. The issue is typical for rigid pavements and solved with the help of the partial depth patch or the full-depth patch. Shrinkage cracking. This is the term for very thin cracks that are not located anywhere near the joints. This type of cracks doesn’t go deep into the pavement structure. Sometimes shrinkage cracking can be very extensive – in this case it is considered a serious distress and fixed with the help of crack sealing. Shrinkage cracking is common in rigid pavements made of PCC (Portland Cement Concrete) and occurs in case of bad setting and curing. Shattered slab. Breaking of a slab due to large load, bad weather conditions or poor quality of materials. Such kind of damage renders the entire lot unusable, so a full replacement is the only option. Weathering. When the weather (cold, excessive moisture, frost shattering) affects the structure of the pavement surface, it is called weathering. The common result of weathering is cracking, chipping of the pavement surface, roughening or increased surface porousness. The solution to this issue is usually defined after a damage analysis. Stripping. Stripping is a surface crack that goes from the bottom of the surface layer and upwards. It happens when the bond between asphalt binder and aggregates is lost. While the factors that cause the bond loss and stripping still require more research, the experts ascribe this kind of disintegration to water damage, because the hydrophobic aggregates usually do not face stripping issues. Blowup. This is the name for a slab that gets cracked or shattered at a joint because of a localized upward movement. This type of distress is caused by hot weather, freeze-thaw damage or D-cracking, creating a serious and hazardous damage. Blowups are repaired with the help of the full-depth patch. Popout. The pockmark-like markings or divots usually appear in PCC due to the poor aggregate durability. They can be repaired with the help of the partial depth patch. Corner spall. The crack intersecting the corner at the joint of the PCC slab is defined as a corner spall. This type of distress is an evidence of the high stress and load applied to the corner of the slab. The pavement exhibiting corner spalls is more vulnerable to moisture infiltration, provides less support and leads to surface disintegration. Joint spall. When the edges of a joint or crack get broken, chipped or cracked, this is called joint spall. Poor quality of materials, heavy traffic load, disintegration of PCC caused by freeze-thaw action are the most common factors that lead to this type of damage. Patching. It is a patch failure. When a patch of new material is applied sloppily to the existing pavement, it makes the surface rougher and, therefore, less usable. Many professionals consider even well-performing patches a defect, because only smooth and intact pavement is an option.

Weathering. When the weather (cold, excessive moisture, frost shattering) affects the structure of the pavement surface, it is called weathering. The common result of weathering is cracking, chipping of the pavement surface, roughening or increased surface porousness. The solution to this issue is usually defined after a damage analysis. Stripping. Stripping is a surface crack that goes from the bottom of the surface layer and upwards. It happens when the bond between asphalt binder and aggregates is lost. While the factors that cause the bond loss and stripping still require more research, the experts ascribe this kind of disintegration to water damage, because the hydrophobic aggregates usually do not face stripping issues. Blowup. This is the name for a slab that gets cracked or shattered at a joint because of a localized upward movement. This type of distress is caused by hot weather, freeze-thaw damage or D-cracking, creating a serious and hazardous damage. Blowups are repaired with the help of the full-depth patch. Popout. The pockmark-like markings or divots usually appear in PCC due to the poor aggregate durability. They can be repaired with the help of the partial depth patch. Corner spall. The crack intersecting the corner at the joint of the PCC slab is defined as a corner spall. This type of distress is an evidence of the high stress and load applied to the corner of the slab. The pavement exhibiting corner spalls is more vulnerable to moisture infiltration, provides less support and leads to surface disintegration. Joint spall. When the edges of a joint or crack get broken, chipped or cracked, this is called joint spall. Poor quality of materials, heavy traffic load, disintegration of PCC caused by freeze-thaw action are the most common factors that lead to this type of damage. Patching. It is a patch failure. When a patch of new material is applied sloppily to the existing pavement, it makes the surface rougher and, therefore, less usable. Many professionals consider even well-performing patches a defect, because only smooth and intact pavement is an option. Pumping. This is the term for the pavement roughness, vehicle hydroplaning (due to water filling the raveled areas) and loose debris. This distress significantly reduces the usability of the pavement and occurs when the bond between the asphalt binder and particles disappears (asphalt binder aging, poor dust coating bonding, surface aggregate segregation, poor construction). The repairs usually include removing the damaged area and either applying a patch (if the area is small) or a removal and overlay of the damaged layer if the area is large. Rutting. This is the type of pavement distress that looks like wheel path depressions. Much like bird baths, ruts get filled with water each time it rains. Rutting occurs in the case of the incompatibility between the pavement surface and subgrade. There are two types of subgrade/surface issues. First, if the subgrade already has ruts because of the load and the pavement follows right in. Second, if it is the surface that exhibits ruts and subgrade caves in under the pressure. In any case, pavement rutting is hazardous for vehicle as the ruts have a tendency to pull vehicles towards the rut path, which can result in an accident. Leveling and overlay is the solution against rutting. Shoving. If you see the deformities that look like waves on the pavement surface, it means that the pavement suffers from the distress known as shoving. As these formations stretch perpendicular to the direction of pedestrians and traffic, they can cause a great inconvenience. The repairs of small areas that exhibit shoving usually consist of removal and patching. However, if the distressed area is large, only an overlay can fix the issue. Swelling. Localized upward bulges on the asphalt surface are the result of swelling. In its turn, swelling is the result of soil expansion because of the moisture or the growth of ice lenses beneath the surface layer. Because this damage goes beyond the surface level, a full-depth patch is the best solution.

Pumping. This is the term for the pavement roughness, vehicle hydroplaning (due to water filling the raveled areas) and loose debris. This distress significantly reduces the usability of the pavement and occurs when the bond between the asphalt binder and particles disappears (asphalt binder aging, poor dust coating bonding, surface aggregate segregation, poor construction). The repairs usually include removing the damaged area and either applying a patch (if the area is small) or a removal and overlay of the damaged layer if the area is large. Rutting. This is the type of pavement distress that looks like wheel path depressions. Much like bird baths, ruts get filled with water each time it rains. Rutting occurs in the case of the incompatibility between the pavement surface and subgrade. There are two types of subgrade/surface issues. First, if the subgrade already has ruts because of the load and the pavement follows right in. Second, if it is the surface that exhibits ruts and subgrade caves in under the pressure. In any case, pavement rutting is hazardous for vehicle as the ruts have a tendency to pull vehicles towards the rut path, which can result in an accident. Leveling and overlay is the solution against rutting. Shoving. If you see the deformities that look like waves on the pavement surface, it means that the pavement suffers from the distress known as shoving. As these formations stretch perpendicular to the direction of pedestrians and traffic, they can cause a great inconvenience. The repairs of small areas that exhibit shoving usually consist of removal and patching. However, if the distressed area is large, only an overlay can fix the issue. Swelling. Localized upward bulges on the asphalt surface are the result of swelling. In its turn, swelling is the result of soil expansion because of the moisture or the growth of ice lenses beneath the surface layer. Because this damage goes beyond the surface level, a full-depth patch is the best solution. Polished aggregate. Small amount or complete lack of rough aggregate particles is called polished aggregate. This usually happens because the aggregate literally gets polished out by traffic. As the result, the skid resistance is decreased, so the area becomes dangerous for vehicles. Bleeding. This is the name for a smooth, shiny black film on the asphalt surface. This is caused by the pavement surface moving upwards because of hot weather, poor mix quality or excessive amount of asphalt in asphalt concrete. This distress removes skid resistance, leaving vehicles vulnerable to hydroplaning. Contaminants. Any chemicals spilled across the pavement surface have a corroding effect, so they eat through the layers and gradually destroy the integrity of the pavement. Spilled antifreeze or similar chemicals are the most common cause of skid resistance. Oil or fuel slippage. Spilled oil or petroleum contain solvents that erode and ruin the pavement surface. Therefore, any oil spots and spills must be cleaned immediately and not left unattended.

Polished aggregate. Small amount or complete lack of rough aggregate particles is called polished aggregate. This usually happens because the aggregate literally gets polished out by traffic. As the result, the skid resistance is decreased, so the area becomes dangerous for vehicles. Bleeding. This is the name for a smooth, shiny black film on the asphalt surface. This is caused by the pavement surface moving upwards because of hot weather, poor mix quality or excessive amount of asphalt in asphalt concrete. This distress removes skid resistance, leaving vehicles vulnerable to hydroplaning. Contaminants. Any chemicals spilled across the pavement surface have a corroding effect, so they eat through the layers and gradually destroy the integrity of the pavement. Spilled antifreeze or similar chemicals are the most common cause of skid resistance. Oil or fuel slippage. Spilled oil or petroleum contain solvents that erode and ruin the pavement surface. Therefore, any oil spots and spills must be cleaned immediately and not left unattended.